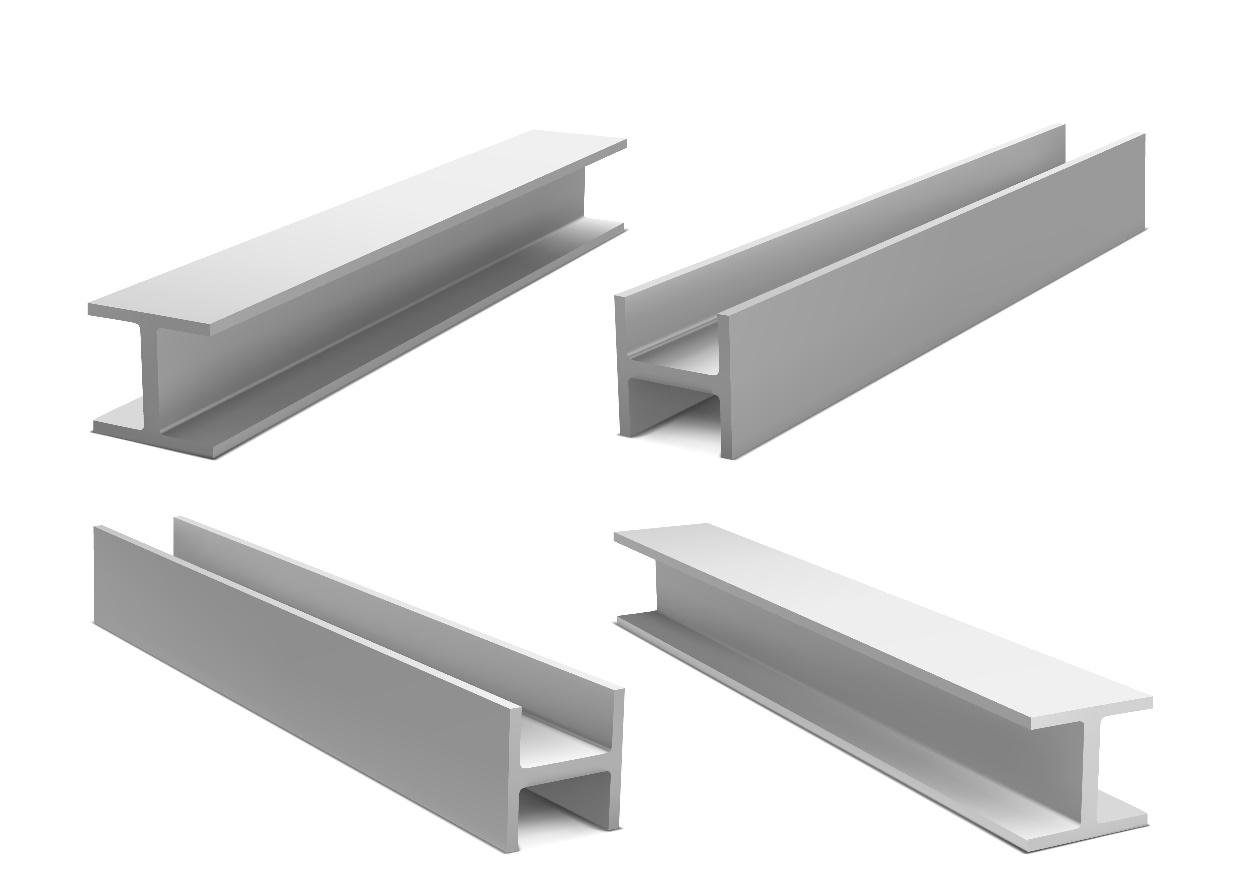

Understanding Stainless Steel Grades for Angles and Channel Bars

Date : Feb 12, 2025It is an extremely popular material in construction and manufacturing industries that has incredible versatility and can never rust. Due to its free from corrosion, high strength and decorative appearance it is suited for angles and channel bars. But it is important to know the different grades of stainless steel in order to meet the right material for the project.

What Are Stainless Steel Grades?

Stainless steel grades can be described as classifications of the specific element contents of the alloy inside the metal as well as its resistance to particular forces. These grades assist manufacturers and buyers to know whether the stainless steel is fit to be used in various applications. The most common grading systems are:

AISI (American Iron and Steel Institute): Uses a three-digit numbering system that the 304 and 316 aerosols can be identified.

EN (European Norm): Hoses alphanumeric codes (for example, 1.4301, 1.4404).

Common Stainless-Steel Grades for Angles and Channel Bars

Grade 304: The All-Rounder

Composition: 18% Chromium, 8% Nickel

Key Features:

Corrosion resistance is very high in most conditions and environments.

Excellent strength levels and relatively ease of forming.

Affordable with easy procurement and accessibility compared to other therapeutic products.

Applications:

The use in construction from buildings to bridges.

Frames and reinforcements utilized in industrial machine.

Decorative applications because its finish is shiny.

Grade 430: The Magnetic Choice

Composition: 16-18% Chromium, Low Nickel

Key Features:

- It has some magnetic properties that set it out from other stainless steel grades.

- Mild environmental resistance, though it lacks even moderate resistance to most corrosives. Cheaper compared to 304 but not as long lasting.

Applications:

- Car interiors and household appliances.

- Indoor decorative elements.

How to Decide on a Grade

- Environment: Evaluate the risks connected with exposure to dampness, chemicals, or saltwater. Choose 316-grade steel when working in very positive environments and choose 304-grade steel otherwise.

- Strength Requirements: The grades such as 304 and 316 are strengthened to standards that makes them ideal for structural purposes.

- Budget: Balance cost and performance. While grade 202 is affordable and unlikely to cored in severe conditions it could be recommended.

- Aesthetic Appeal: In applications where the stainless steel is on the surface of the object or a structure, opt for any of the glossy grades, 304 or 316 for instance.

Conclusion

The different grades of stainless steel is crucial to know when choosing the right material that will be used in angles and channel bars. By learning about the properties and uses of the different types such as the 304, the 316 for marine use or the more affordable 202, you will have a sound decision.